-

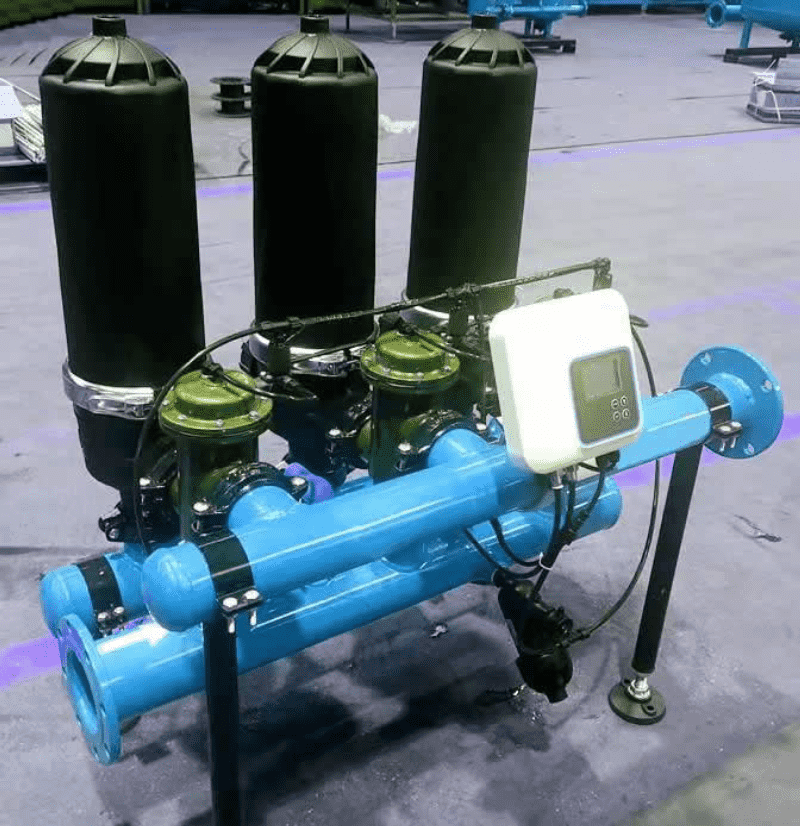

Laminated Filter

Laminated filters, thin sheets of a specific color of plastic with a number of grooves of a certain micron size etched on either side. A stack of the same pattern is pressed against a specially designed brace. When pressed by a spring and liquid pressure, the grooves between the sheets cross to create a deep filter unit with a unique filter channel. The filter unit is housed in a super strong performance engineering plastic filter cylinder to form the filter. When filtering, the filter stack is pressed by spring and fluid pressure, the greater the pressure difference, the stronger the compression force. Ensure self – locking efficient filtration. The liquid flows from the outer edge of the laminate to the inner edge of the laminate through the groove, and passes through 18 ~ 32 filtration points, thus forming a unique deep filtration. After the filter is finished, manual cleaning or automatic backwashing can be done by loosening between the sheets manually or hydraulically.

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur