General Introduction of FRP Tank Series

TOPTION FRP plant produces various horizontal and vertical FRP storage tanks, FRP containers, and FRP large-scale series of FRP pressure vessels. Different types of high-quality resins are selected according to the medium stored by the user, which consists of a high-resin content corrosion-resistant liner, a leakproof layer, a fiber-wound strengthening layer, and an outer protective layer. The product's working temperature is between -50℃ and 80℃, and the pressure resistance is generally below 6.4MPa. It has the advantages of pressure resistance, corrosion resistance, aging resistance, and long service life. Additionally, FRP has the characteristics of lightweight, high strength, leak prevention, insulation, non-toxicity, and smooth surface. Fiberglass products can be widely used in the petroleum, chemical, textile, printing and dyeing, power, transportation, food and beverage brewing, biological and pharmaceutical industries, as well as in water supply and drainage, seawater desalination, water conservancy and irrigation, and national defense engineering.

Introducing the following four types:

1. FRP Vertical Storage Tank 2. FRP Horizontal Storage Tank 3. FRP Transport Tank 4. FRP Reactor

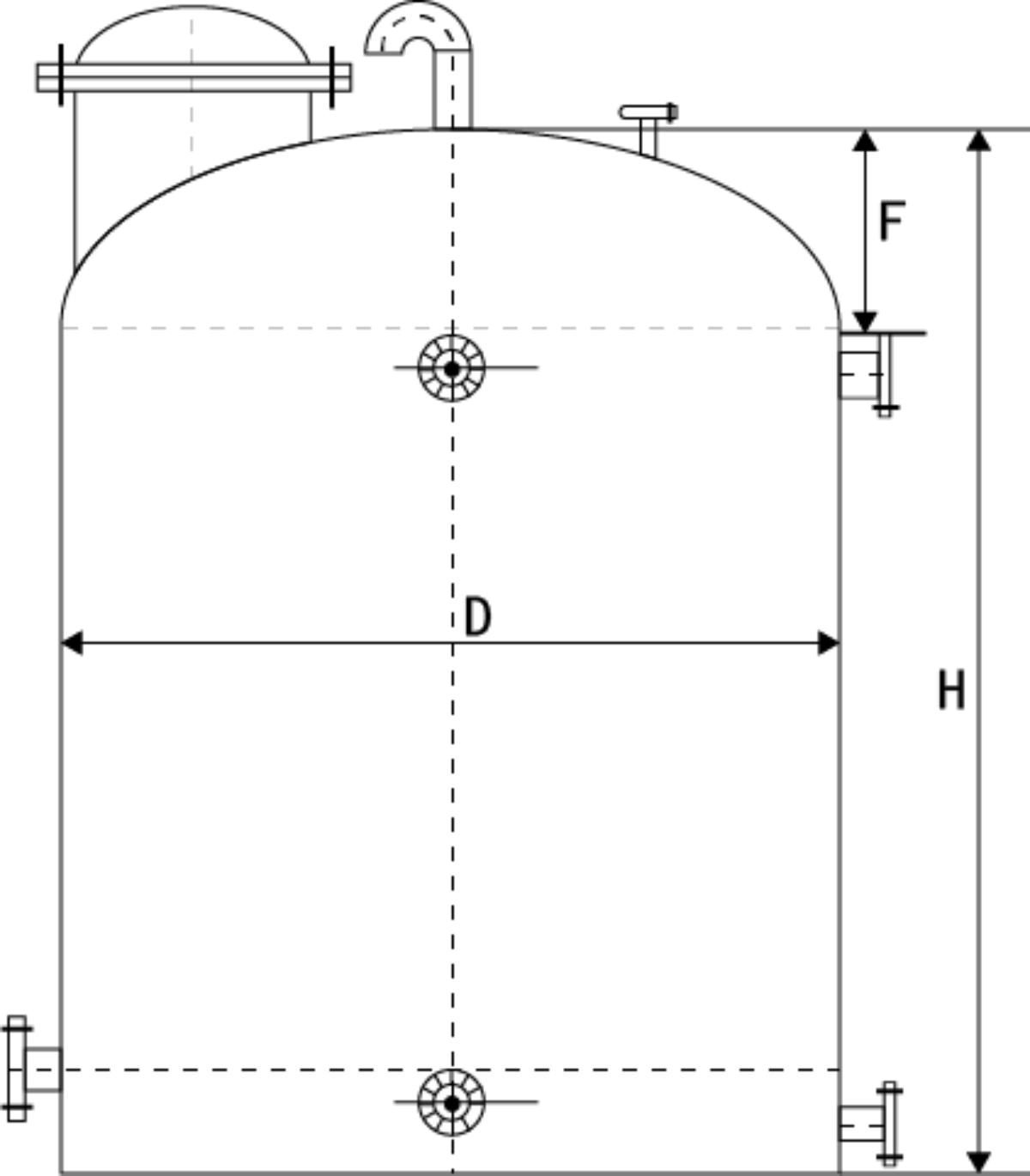

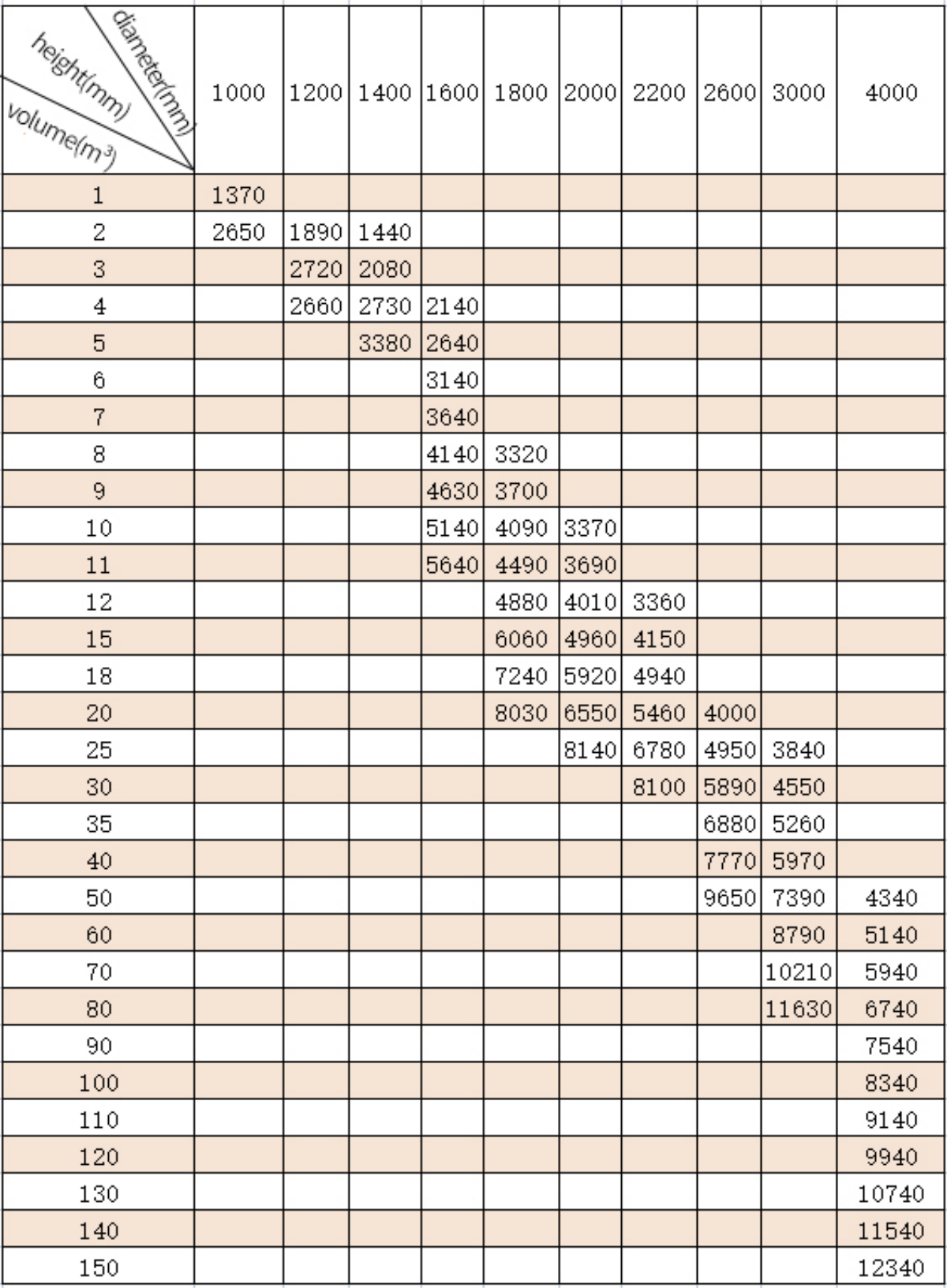

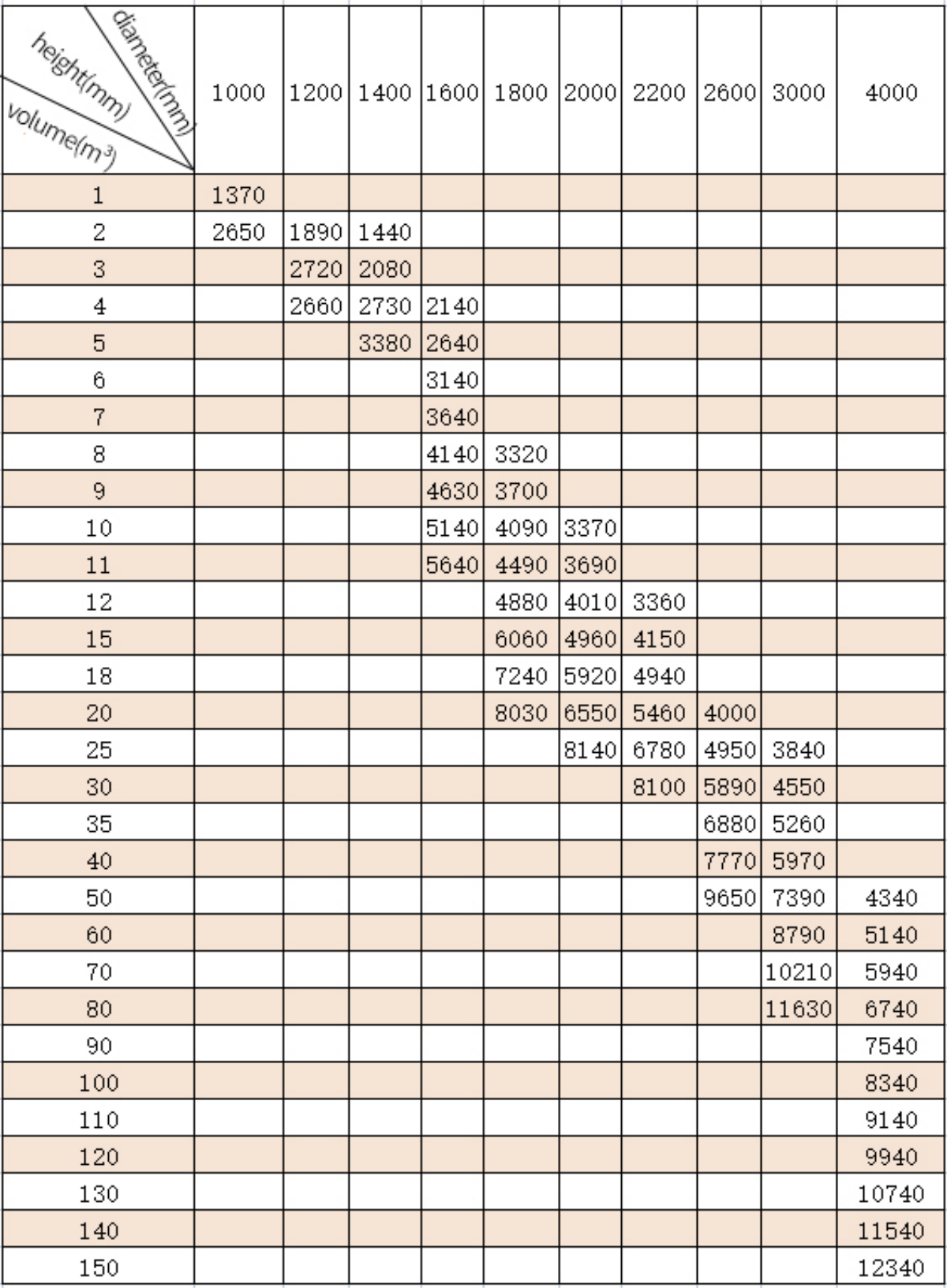

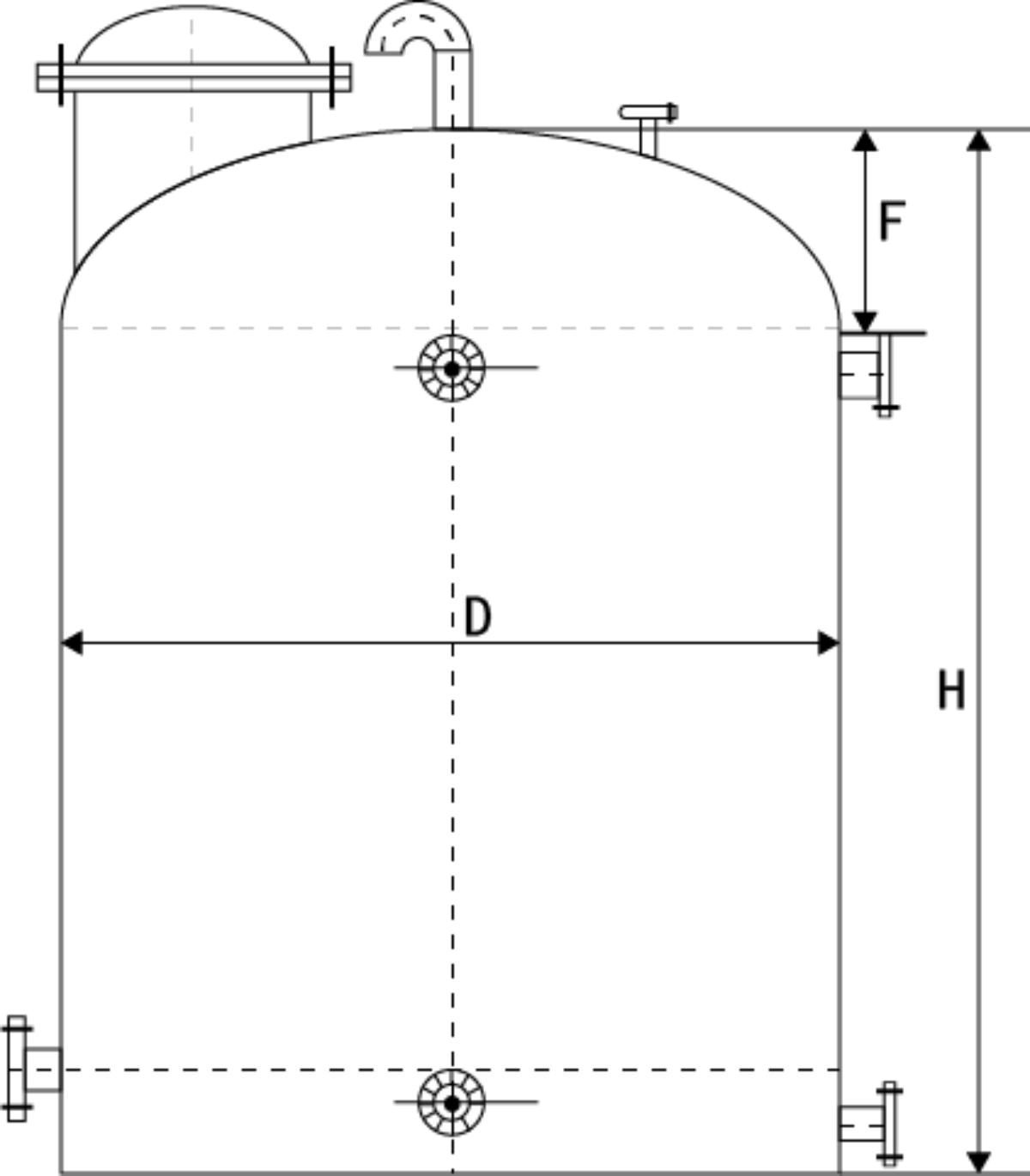

Fiberglass/FRP Vertical Storage Tank

The fiberglass vertical storage tank is a device used for storing liquids. It is usually made of fiberglass-reinforced plastic, with high durability, high temperature resistance, corrosion resistance, and hygiene. The shape of the FRP vertical storage tank is cylindrical or square, and its volume can be customized according to requirements. Due to its large volume advantage, it is suitable for places that require large-capacity storage. Additionally, it has a low center of gravity, occupies a small area, and is easy to install and maintain.

FRP vertical storage tank is widely used in the fields of chemical, petroleum, papermaking, food, electronics, pharmaceuticals, and packaging and transportation. It is resistant to corrosion by various acids, alkalis, salts, and organic solvents.

1.FRP acid-resistant storage tank: FRP hydrochloric acid tank, FRP sulfuric acid tank, fiberglass phosphoric acid tank, glass steel nitric acid tank, FRP organic acid tank, fiberglass fluosilicic acid tank, FRP hydrofluoric acid tank, etc.

2.FRP rupture-resistant storage tank

3.FRP Saltwater storage tank, FRP sewage storage tank

4. Food-grade FRP storage tank: Fiberglass/FRP vinegar storage tank, FRP vinegar container, FRP soy sauce container, FRP pure water storage tank, etc. FRP/PVC composite tank, FRP/PP composite tank.

FRP Vertical Storage Tank Plan and Technical Specifications.

FRP Horizontal Storage Tank

Fiberglass reinforced plastics/FRP horizontal storage tank is also a common device for storing liquids or gases. It is suitable for storing various media, such as food, non-food, chemicals, chemical raw materials, and various liquid chemical drugs. The capacity of a FRP horizontal storage tank is larger than that of a FRP vertical storage tank, making it suitable for storing large quantities of materials. Its advantages include a lower center of gravity, smaller footprint, and easy installation and maintenance. The materials used in a horizontal storage tank can be fiberglass or metal, but fiberglass has higher corrosion resistance and durability, making horizontal fiberglass/FRP storage tanks better suited for storing required media. Horizontal fiberglass storage tanks have good resistance to medium corrosion and sufficient physical and mechanical properties to meet the requirements for filling. They can be used for organic and inorganic solvents, chemical and electrochemical corrosive media, storage, transfer and production requirements, transfer, transportation and elimination of non-electrolytic fluids and anti-supporting shear and burial with load mechanical requirements. The design is highly flexible and the tank wall structure performance is excellent. Fiberglass winding can adjust the physical and chemical properties of the storage tank by changing the resin system or strengthening materials to adapt to the needs of different media and working conditions. The FRP tank body carrying capacity can be adjusted through the design of the structural layer thickness, winding angle, and wall thickness structure to adapt to different pressure levels, capacity sizes, and the needs of certain special performance fiberglass storage tanks, which cannot be compared with isotropic metal materials.

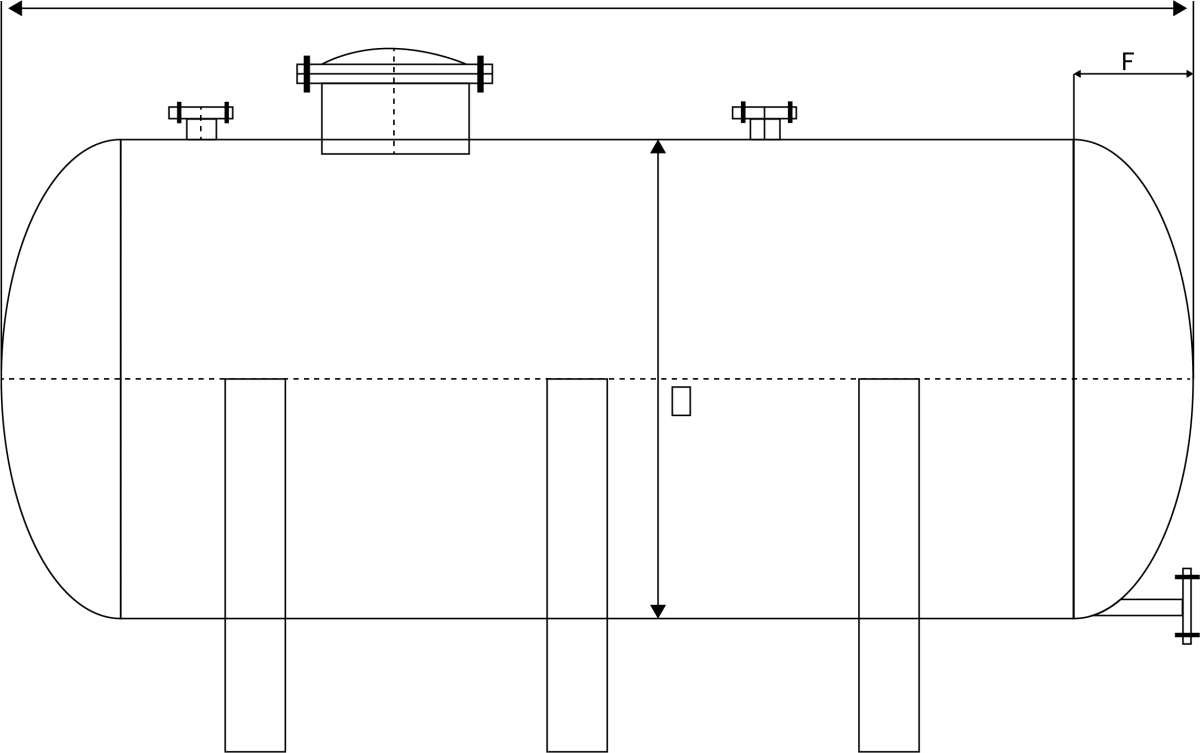

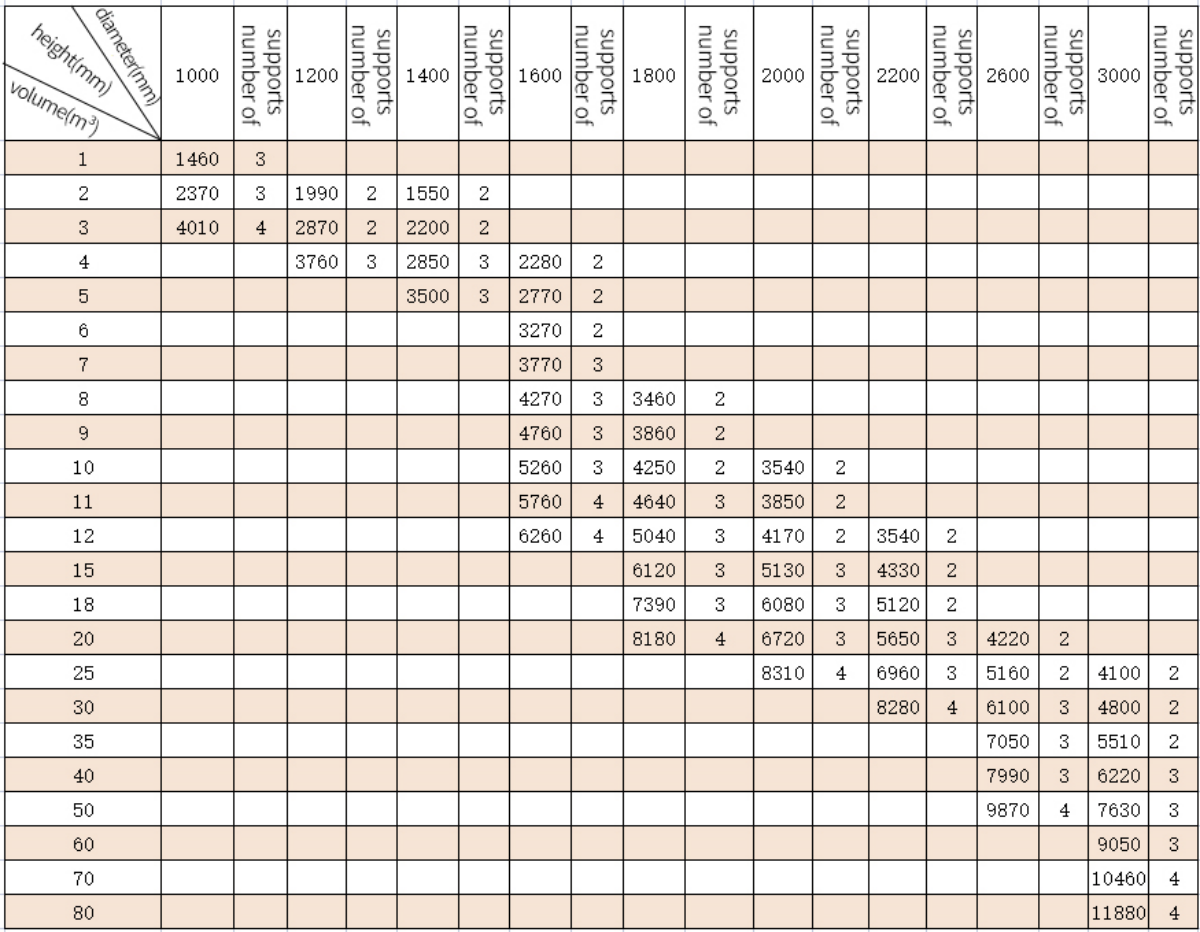

Fiberglass Horizontal Storage Tank Plan and Technical Parameters

Fiberglass Transport Tank

A fiberglass/FRP transport tank generally refers to equipment that can be used to transport liquid or gaseous goods via highways or waterways. Compared with other materials, fiberglass/FRP transport tanks are lightweight, corrosion-resistant, erosion-resistant, weather-independent, safe and hygienic, and are widely used in the transportation of goods in industries such as food, chemical, power, and pharmaceuticals. According to different requirements, FRP transport tanks are designed in different shapes and capacities, and different resins and reinforcing materials are used to adapt to different media.

FRP Reaction Vessel

A reaction vessel (also known as a reaction tank or reaction pot) is a container used for physical or chemical reactions. The fiberglass/FRP reaction vessel is one type of reaction vessel, commonly made of fiberglass reinforced plastic, which is durable, heat-resistant, corrosion-resistant, and hygienic. The FRP reaction tank is widely used in industries such as beverage, pharmaceutical, food processing, and chemical manufacturing. Its design can be adjusted according to the properties of the medium, temperature, and pressure requirements, and can also be operated under negative pressure to ensure the safety of operators.