General Introduction

EDI Equipment for short, also known as continuous electric desalting technology, it will be a scientific integration of electrodialysis technology and ion exchange technology, through the cationic, anionic membrane on the cation, anion through the selection and ion exchange resin on the water ion exchange action, under the action of the electric field to achieve the directional migration of ions in water, so as to achieve the depth of water purification and desalting, and produced by hydroelectricity Hydrogen ion and hydroxide ion can continuously regenerate the filling resin, so EDI water treatment production process can continuously produce high-quality ultra-pure water without the regeneration of acid and alkali chemicals.

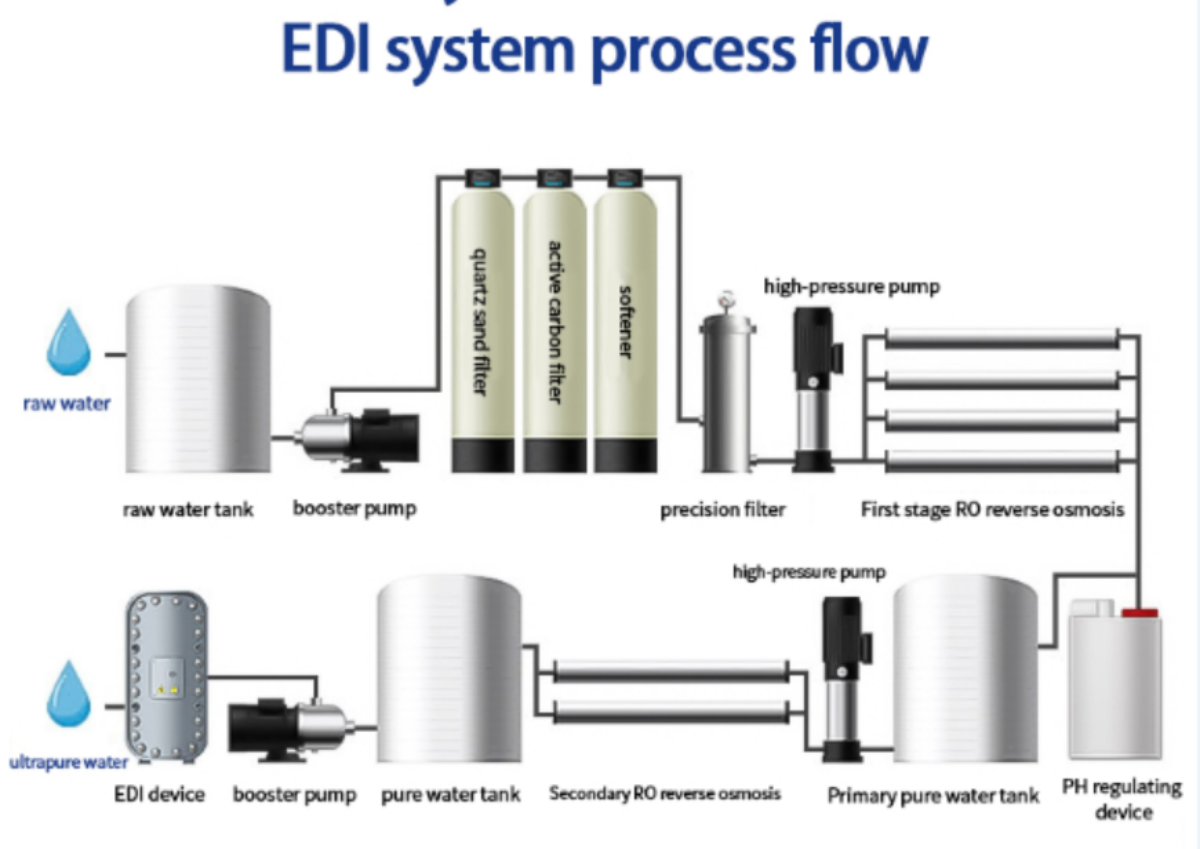

Working Process

EDI water treatment equipment workflow is divided into the following steps:

1. Coarse filtration: Before sending the pump from tap water or other water sources into EDI equipment, it is necessary to carry out coarse filtration to remove large particles of impurities and suspended particles, so as to avoid affecting the treatment effect when entering EDI pure water system.

2. Washing: After the precision filter enters EDI ultra pure water equipment, it is necessary to wash the precision filter through circulating water to remove impurities and dirt attached to the surface of the filter.

3. Electrodialysis: The ions in water are separated by electrodialysis technology. Specifically, EDI devices use a current applied between two electrodes to drive ions out of the water through the flow of cation and cation ions on the ion membrane. The advantage of electrodialysis is that it does not require the use of chemicals or regenerants and is thus more environmentally friendly.

4. Regeneration: The separated ions are removed in EDI equipment through cleaning and reverse washing, so as to maintain the operating efficiency of the equipment. These ions will be discharged through the wastewater pipe.

5. Removal of purified water: After EDI water treatment, the electrical conductivity of output water will be lower and more pure than before entering the equipment. The water can be put directly into production or stored for later use.

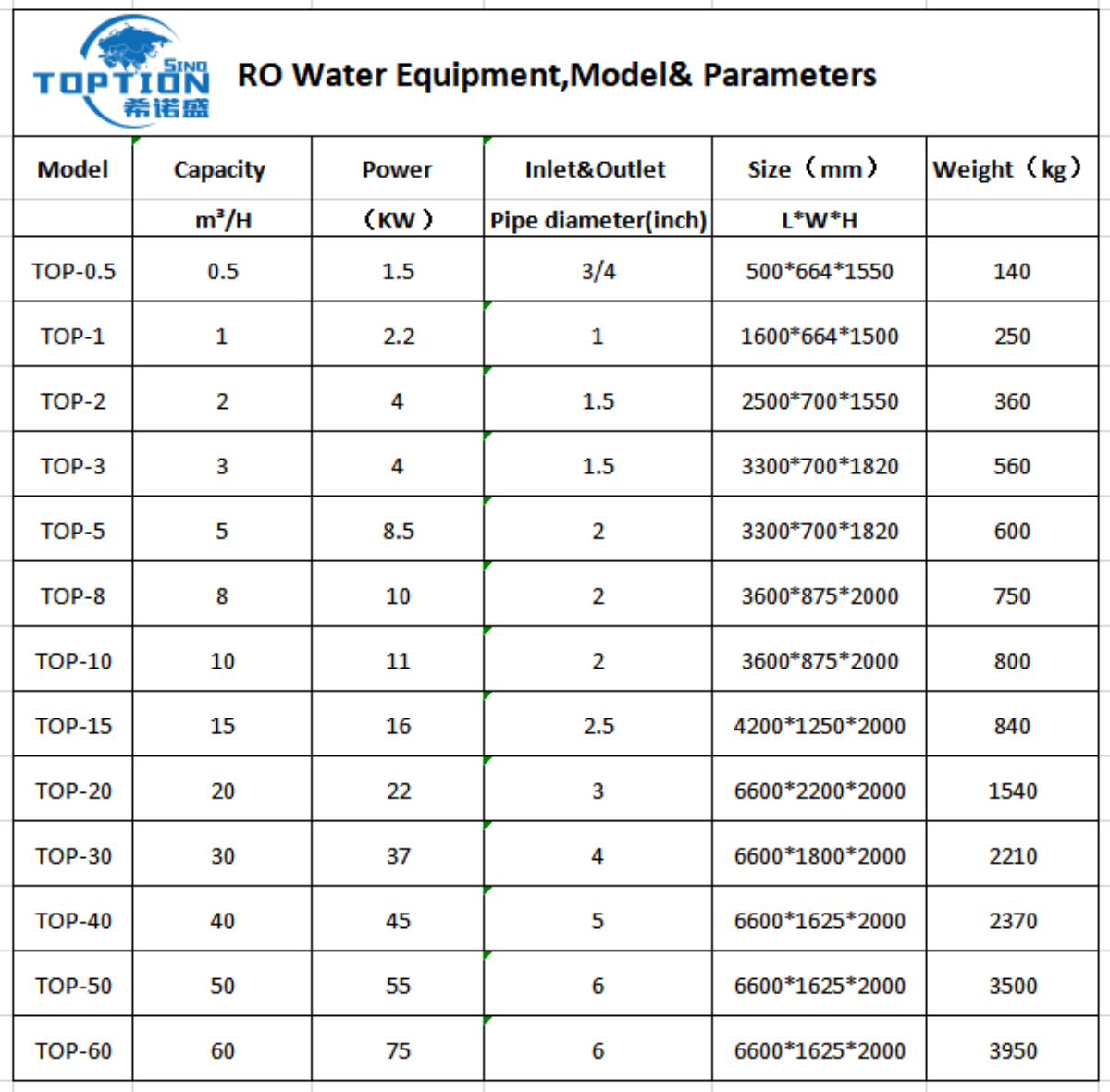

Model and Technical Parameters

Toption EDI water plant equipment , has our own brand, below is the Model and Parameter:

EDI application field

EDI water treatment system has the advantages of advanced technology, compact structure and simple operation, which can be widely used in electric power, electronics, medicine, chemical industry, food and laboratory fields. It is the green revolution of water treatment technology. Among them, the most widely used is urea equipment industry and electronic products industry.

Automotive urea industry

EDI water treatment equipment is widely used in the automotive urea industry to produce high quality urea water, urea water is one of the essential components of Diesel Exhaust Fluid (DEF), DEF is a liquid used in SCR equipment to reduce nitrogen oxides (NOx) emissions from diesel engine exhaust. In urea aquatic production, EDI equipment is mainly used to remove ions from water and produce higher purity water. This deionized and purified water is commonly used to prepare urea water to ensure that it meets the DEF standard. Otherwise, ions in urea water may be deposited in the SCR system and form solid particles affected by clogging. This will affect the quality and performance of DEF, which will affect the working efficiency of the catalyst and lead to substandard NOx emissions. EDI ultrapure water equipment can be used to treat water alone or in conjunction with other technologies such as RO and mixed-bed ion exchangers. The resulting water conductivity can reach 10-18-10-15 mS/cm, which is higher than that produced using traditional ion exchange technology. This makes it one of the common techniques used in DEF production, especially in the high-end market where higher purity and quality are required. Therefore, EDI technology can improve and guarantee the quality of urea water, improve the efficiency and reliability of SCR system, and better safeguard the environmental protection measures in terms of air quality.

Toption water treatment equipment, over the years at the same time focus on vehicle urea equipment research and development and manufacturing. Vehicle urea production equipment has semi-automatic line and automatic line two, can be multi-purpose, commonly used as glass water, antifreeze, car wash liquid, all-round water, tire wax can be produced.

Electronic products industry

EDI system is widely used in the electronic industry to produce ultra-pure water. Ultra-pure water is widely used in semiconductor production, liquid crystal display manufacturing and electronic components manufacturing in the electronics industry. These applications require highly pure water to ensure high quality and stability of the product. EDI ultra pure water equipment provides an efficient, low-cost, and reliable means of producing sufficient purified water to meet these needs. The semiconductor industry needs high purity water to clean the surfaces of chips and other devices. The cleaning process must remove hardness ions, metal ions and other impurities, preferably up to 9 nm (nm) level, EDI equipment can achieve this level. In LCD manufacturing, high quality ultra-pure water is needed for cleaning and rinsing ITO film and glass substrate to ensure that products can meet high quality requirements. Automatic EDI equipment can provide high quality ultra-pure water. In short, the application of EDI pure water equipment in the electronic industry is to produce high quality and high purity water, which can meet the demand of electronic product manufacturing and ensure product quality and stability.